Jungheinrich Pneumatic Tire Forklift Houston

Inspecting your Fork Truck for Safety

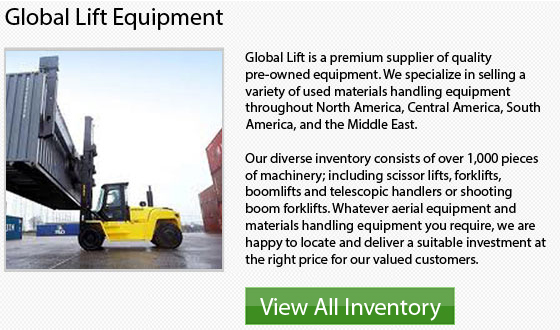

A fork truck, like any industrial equipment, must be utilized with care. Unlike a car, a fork truck is steered from the back wheel and therefore has a different center of balance. Anyone operating a fork truck and everyone working in the vicinity of this particular equipment needs to understand safe operating measures and workplace safety guidelines.

Safe operation of a lift truck before driving it will include a visual inspection. Worn tires and fuel leaks are potential dangers that an operator has to inspect. The lifts, forks as well as the overhead guard should be carefully checked. The safety handle must be used only when the forklift is being mounted.

To guarantee that they are operating properly, the alarms, lights and horns should be inspected on a regular basis while the monitors and gauges may need to be adjusted. Safety belt should be fastened and seat adjusted before starting the truck.

To prevent tipping the machinery, take turns cautiously and always choose the low rate speed when driving. If the load blocks the operator's vision, the truck should be driven in reverse gear. Be alert of the location of any pedestrians and obstacles when driving.

To prevent any possibility of injury, the operator should always sit within the cage enclosure and keep all parts of the body inside. The forks should be kept a few inches above the ground while driving. Never lower or raise lifts while you are driving or the truck can become unstable. Do not permit anyone to walk under lift when the engines are running.

Stopping at intersections and watching for approaching traffic are basics for driving safely. It is really a good idea to sound the horn before proceeding as well as occasionally when operating in aisles. That way, you would warn any approaching person to your presence.

- Skyjack Rough Terrain Scissor Lifts Houston

Rough Terrain Scissor Lifts Mid-Size SJ 7127 The SJ 7127 provides both powerful and solid design elements so as to be capable of meeting the demands of the most challenging environments at the job location.... More - Jungheinrich Dual Fuel Forklift Houston

On construction locations all over the world, lift trucks, bulldozers and bobcats have become essential machinery. Forklifts are versatile industrial machinery which come in lots of sizes from fairly small to extremely huge. These types... More - Yale IC Forklifts Houston

Internal Combustion Lift Trucks The IC forklift belongs in the class V and IV forklift classification. They can be diesel, liquid propane or gas units. Mainly, the ICE or also referred to as internal combustion... More - CAT Rough Terrain Forklift Houston

The rough terrain lift truck is a machine designed particularly to carry out tasks on challenging terrain which a traditional pneumatic tire forklift is not able to complete. This tire design allows the equipment to... More - Toyota Forklifts Houston

Forklifts were first made almost 100 years ago, and were once only simple equipment that were manufactured to transport pallets from one place than another. Sophisticated lift trucks nowadays, are now offered in numerous designs,... More