Crown Reach Forklifts Houston

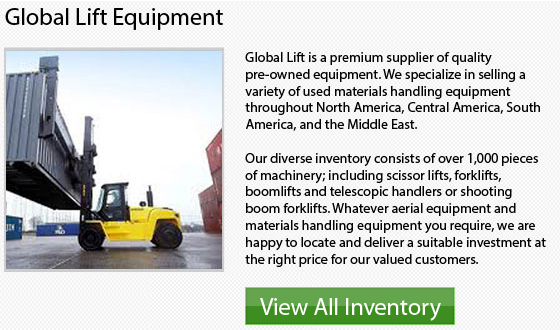

In the beginning of the 20th Century, lift trucks were initially introduced. They have come a long way since the first models. Their original purpose was to move supplies in an efficient manner. This is still the main objective. There are an array of different kinds of lift trucks utilized in the material handling business.

Motorized Pallet Truck Rider Type

The rider type of lift truck is a motorized kind of the pallet jack. This equipment is commonly utilized to move pallet trucks over extreme distances, including movement between storage areas or departments. There is a different version called the walkie version. This model lacks the higher speeds and the operator platform. Low cost and hi maneuverability make these vehicles a better choice for operations where frequent load movement is necessary. Some of the common choices include double pallet length forks which enable you to move 2 pallets in a single trip.

Electric Counterbalanced Lift Truck

The Electric Counterbalanced Lift Truck is capable of stacking and racking loads, utilized to move load trailers, as well as pallet loads all over a facility. This kind has a wide variety of available attachments and needs to have a wide aisle for turning.

Internal Combustion Counterbalanced Lift Truck

IC counterbalance lift trucks work quite like the electric lift truck. Propane models could be utilized both indoors or outdoors so long as there is ample ventilation.

Order Selector

The order selector has been designed to move palleted loads out of and into selective racks. The VNA or also known as very narrow aisle vehicles works in aisles less than six feet wide. These Order Selectors are also known as Order Pickers.

Reach Truck

Narrow aisle trucks which are 8 to 11 feet are made specially for racked pallet storage. Double-deep versions load pallets 2-deep in special double-deep racking systems. These types of reach trucks are really efficient and could make racked pallet storage a more streamlined process.

- Skyjack Rough Terrain Scissor Lifts Houston

Rough Terrain Scissor Lifts Mid-Size SJ 7127 The SJ 7127 provides both powerful and solid design elements so as to be capable of meeting the demands of the most challenging environments at the job location.... More - Jungheinrich Dual Fuel Forklift Houston

On construction locations all over the world, lift trucks, bulldozers and bobcats have become essential machinery. Forklifts are versatile industrial machinery which come in lots of sizes from fairly small to extremely huge. These types... More - Yale IC Forklifts Houston

Internal Combustion Lift Trucks The IC forklift belongs in the class V and IV forklift classification. They can be diesel, liquid propane or gas units. Mainly, the ICE or also referred to as internal combustion... More - CAT Rough Terrain Forklift Houston

The rough terrain lift truck is a machine designed particularly to carry out tasks on challenging terrain which a traditional pneumatic tire forklift is not able to complete. This tire design allows the equipment to... More - Toyota Forklifts Houston

Forklifts were first made almost 100 years ago, and were once only simple equipment that were manufactured to transport pallets from one place than another. Sophisticated lift trucks nowadays, are now offered in numerous designs,... More