Caterpillar Lift Trucks Houston

How to lessen the cost of damage to fork lift trucks

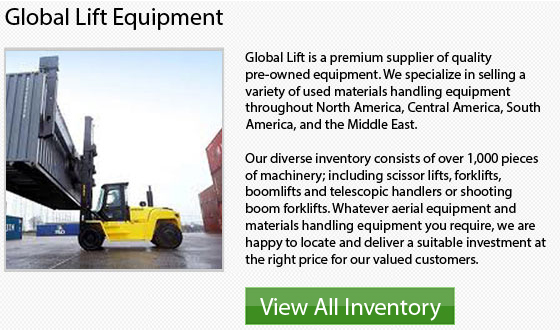

Regardless of the workplace, there are some common causes of damages to forklift trucks. Instances of damage can be extremely costly. Costs usually relate to costs of repair and staff downtime. Fortunately, most kinds of forklift truck damage could be avoided. By following these simple steps, fleet operators could ensure that repair expenses and downtime are prevented or minimized.

Check that the machinery is appropriate for the task and the surroundings. Carry out safety checks on truck components and vital systems. Be sure that operators of forklifts are well trained and that supervision is provided. Examine the layout of the warehouse/operating area to make certain it facilitates movement. Develop a repair/maintenance plan which could guide actions when anything goes wrong.

Even if the working environment is usually the cause of accidents, fault can be sometimes be the actions of the operators. A safe working environment involves having the correct machinery for the application.

Taking a long-term and coordinated view of fleet management is the most cost-effective approach. The instances of damage can be reduced a lot by having the same company which supplied the trucks train the drivers and carry out maintenance and repairs. The company can also offer suggestion regarding the warehouse design.

- Skyjack Rough Terrain Scissor Lifts Houston

Rough Terrain Scissor Lifts Mid-Size SJ 7127 The SJ 7127 provides both powerful and solid design elements so as to be capable of meeting the demands of the most challenging environments at the job location.... More - Jungheinrich Dual Fuel Forklift Houston

On construction locations all over the world, lift trucks, bulldozers and bobcats have become essential machinery. Forklifts are versatile industrial machinery which come in lots of sizes from fairly small to extremely huge. These types... More - Yale IC Forklifts Houston

Internal Combustion Lift Trucks The IC forklift belongs in the class V and IV forklift classification. They can be diesel, liquid propane or gas units. Mainly, the ICE or also referred to as internal combustion... More - CAT Rough Terrain Forklift Houston

The rough terrain lift truck is a machine designed particularly to carry out tasks on challenging terrain which a traditional pneumatic tire forklift is not able to complete. This tire design allows the equipment to... More - Toyota Forklifts Houston

Forklifts were first made almost 100 years ago, and were once only simple equipment that were manufactured to transport pallets from one place than another. Sophisticated lift trucks nowadays, are now offered in numerous designs,... More