Jungheinrich Double Reach Forklifts Houston

Forklift Material Handling

Businesses can ultimately experience changes in the handling needs over time. There are some things used to maintain optimal output such as expanded geographical coverage, more SKUs, and need to lessen inventories. There have been numerous advances within material handling technologies and processes in the past several years. Various tools are evolving at a very fast rate and have the potential to effect productivity significantly.

Forklift Battery & Charging Technology

Now is the perfect time to consider converting from conventional, IC forklifts to electric lift trucks. The technology behind modern electric lift truck charger and battery combinations is well ahead of the technological curve. Electric systems are capable of providing a lot more power for longer periods than ever before. The current line-up of electric lift truck units provide run-times and capacities which surpass older units. Developments in both charger and battery technologies help contribute to more environmentally sound methods inside warehouses all over the globe.

Lithium-Ion Batteries, also called Li-ion batteries, are the wave of the future. This leading edge technology is having a major effect on electric lift truck usage. The advantages of Li-ion batteries are size and run times and low maintenance. They can be made in smaller sizes than traditional lead acid batteries and are capable of holding up to six times the charge. They have zero memory, which enables them to maximize charging.

Electric or Internal Combustion Lift Truck

Consider purchasing an electric forklift, whether you are replacing an old truck or looking for your first forklift. Remember that the environmental, technological and legislative issues involved in forklift usage and technology is subject to change. Kindly review this easy-to-follow guidelines when thinking about whether an IC or an electric truck best meets your needs.

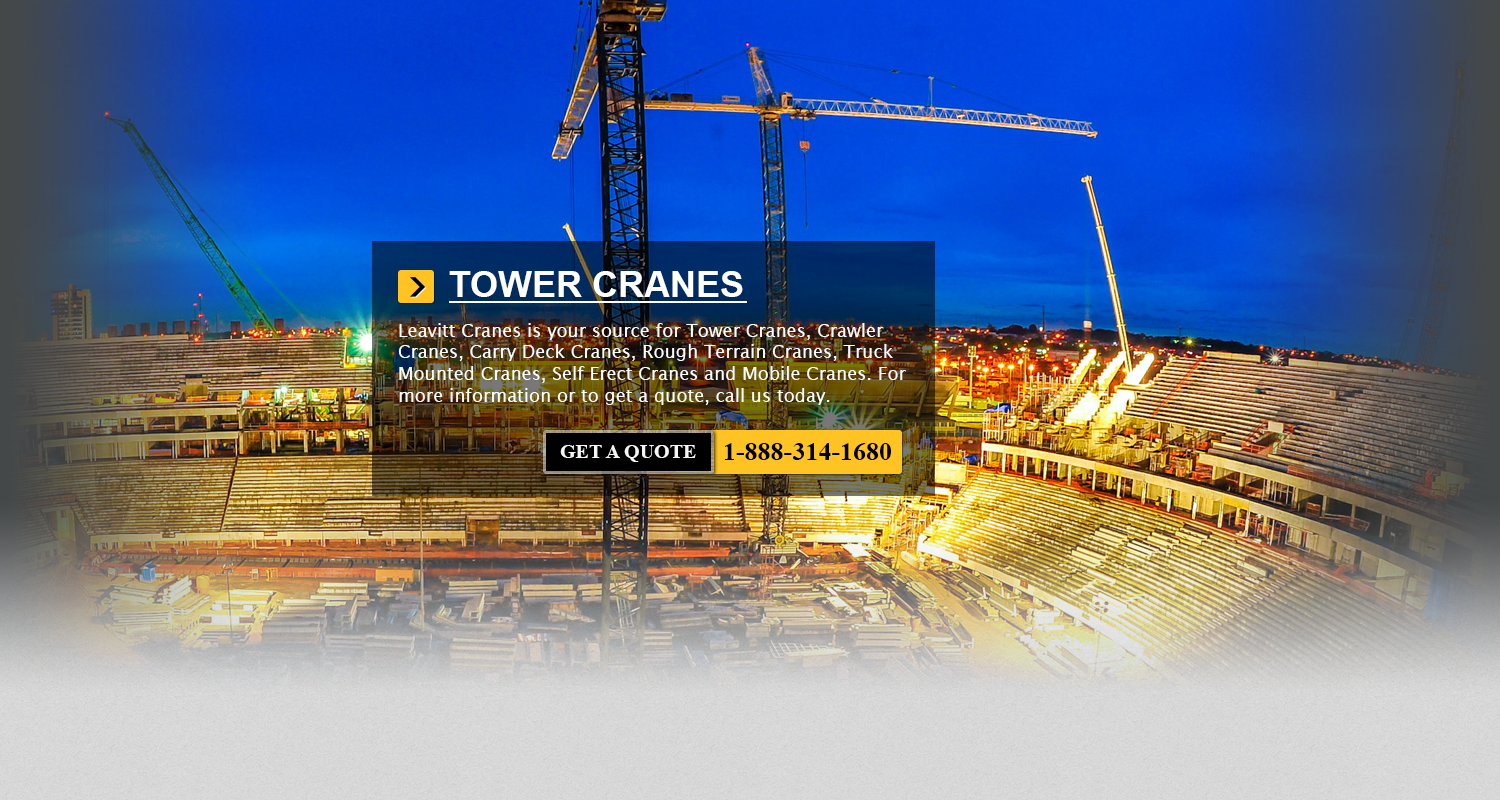

- Pecco Tower Cranes Houston

Different Types of Crawler-Mounted Cranes In order to be able to power a large range of machines, industrial wheel tractors were modified during the 1920s, by McCormick-Deering and Fordson. Like for instance, half-swing cranes and... More - Jungheinrich Dual Fuel Forklift Houston

On construction locations all over the world, lift trucks, bulldozers and bobcats have become essential machinery. Forklifts are versatile industrial machinery which come in lots of sizes from fairly small to extremely huge. These types... More - Yale IC Forklifts Houston

Internal Combustion Lift Trucks The IC forklift belongs in the class V and IV forklift classification. They can be diesel, liquid propane or gas units. Mainly, the ICE or also referred to as internal combustion... More - CAT Rough Terrain Forklift Houston

The rough terrain lift truck is a machine designed particularly to carry out tasks on challenging terrain which a traditional pneumatic tire forklift is not able to complete. This tire design allows the equipment to... More - Fantuzzi Container Handlers Houston

Side Loader Light Range Fantuzzi has developed container handler models in the 3-4 tonne variety that operate off of liquid propane gas, diesel or electric fuel sources. Each of these models have been designed with... More