Komatsu Warehouse Forklifts Houston

Warehouse Forklift Maintenance

Forklifts need a proper maintenance program to help increase the equipments lifespan and is an important factor in allowing the equipment to run safely and effectively. Completing forklift inspection on a regular basis and doing preventive maintenance on a routine basis would help to ensure the safe and efficient use of the equipment.

Daily Checklist

The daily checklist is an important tool in any forklift maintenance program. These checklists will help to document any and all possible issues. They are required by the OSHA or the Occupational Safety and Health Administration. The daily checklists can also be audited by OSHA during any routine inspection. Operators are required to complete the inspection from the start of their shift. If any major problems are found, the forklift could not be used until the issue has been fixed.

Maintenance and Safety Go Hand-in-Hand

Within the US, there are about one hundred deaths related to forklift mishaps and statistic show that nearly 20,000 individuals are seriously injured as well. This number represents 54 people per day, 7 days a week, for the entire year. Many of these mishaps can be easily prevented if the forklift had been properly serviced and maintained. In some circumstances, it may seem like a cost savings to skip or delay regular maintenance, however, these savings would pale in comparison to the cost of one mishap.

Items to be Serviced

The manufacturers owner guidebook would include a recommended maintenance schedule. Schedules will differ depending on every manufacturer and every model of forklift. Each schedule will contain a variety of basic items. For example, in a combustion engine, the engine oil and the oil filter should be replaced periodically. Hydraulic levels must be checked too. Be sure to check hoses for any signs of cracking. Additional items include the brakes, the transmission and the electrical systems of the forklift.

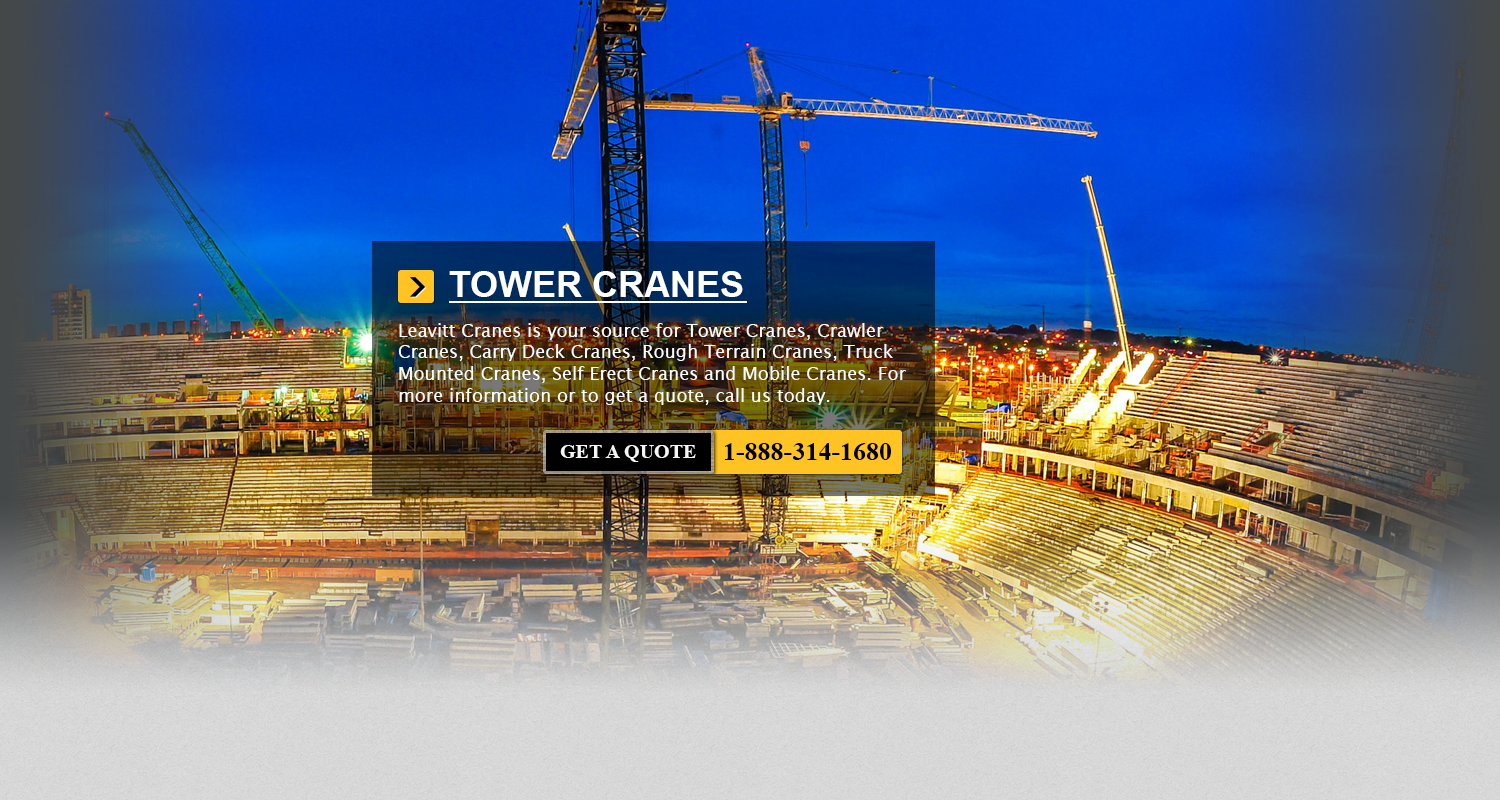

- Pecco Tower Cranes Houston

Different Types of Crawler-Mounted Cranes In order to be able to power a large range of machines, industrial wheel tractors were modified during the 1920s, by McCormick-Deering and Fordson. Like for instance, half-swing cranes and... More - Yale Narrow Aisle Forklifts Houston

Yale is a leading manufacturer of zero emissions electric lift trucks within the North American Market. The company was among the first to start using other control technology and the energy efficient AC motor. Yale's... More - Yale Gas Forklifts Houston

Very Narrow Aisle and Narrow Aisle Trucks: Some forklifts have NA features or VNA features. To be able to function safely and efficiently, nearly all counterbalanced trucks need at least 11 feet of aisle width.... More - Skyjack Knuckle Boom Lifts Houston

Boom Truck Boom trucks are quite similar to cranes and can be equipped with a winch for lifting. This will depend upon the weight and size of the vehicle, which determines the type of load... More - Fantuzzi Container Handlers Houston

Side Loader Light Range Fantuzzi has developed container handler models in the 3-4 tonne variety that operate off of liquid propane gas, diesel or electric fuel sources. Each of these models have been designed with... More